Announcing The World's Largest Collection of

16,000 Woodworking Plans

(Make sure your sound is turned on. Please wait up to 10 secs for the video to load)

Watch This Video To The End & Get Access To 16,000 Plans!

Lifetime Member Deal: $67

Get Instant Access To 16,000 Plans >>

This is a one-time purchase.

I reserve the right to end this anytime after in 2 days

From The Desk Of Ted Mcgrath

Re: Woodworking made easy...

Dear Fellow Woodworker,

Have you ever:

- Wanted to build something, because you cannot find it "retail"?

- Thought of making something custom for a specific need but don't know where to start?

- Wanted to buy nice furniture but can't afford high quality pieces?

- Thought of upcycling wood you found but afraid of messing it up?

- Struggle to find detailed plans to build your dream project?

These are the issues I faced years ago when I started woodworking

... and it is the same challenges many of my students are still facing today.

"Woodworking shouldn't be that difficult!"

Now if you want to create the projects you've dreamed of - quickly and easily...

Instead of spending days, months or years looking for something or god forbid, spending a fortune hiring someone to do it for you...

And you crave the satisfaction of creating something beautiful with your own hands,

Then this may be the most important letter you'll ever read...

Ted "Woody" Mcgrath

Certified Master Woodworker, Educator, Trainer, Author, Member of AWI

“Here's The BIG Problem...”

When I started looking online for plans and buying magazines, here's what I discovered:

Most plans and woodworking magazines are COMPLETE GARBAGE.

Here's why:

- Plans are NOT specific enough - They either lack a step or they lack descriptions or measurements.

- Instructions that leave out VITAL information, assuming that you are experienced enough to "fill in the blanks"

- Assuming you're a master craftsman with access to expensive tools and a large workshop!

- Plans that are too complex for beginners that require thousands of dollars in high-end machinery!

And in many cases, there is simply NOT enough detail!

One of projects I saw was for a modern wardrobe but the details on how to put it together were terrible.

You have to start guessing at where to attach carriage bolts, etc.

Another was that the top back board is not straight as it has design to it which was not explained.

So I took paper template and drew out and traced on boards best I could for one of my students.

These so called "step by step" plans make woodworking

No wonder woodworking seem so hard!

So I've Decided To Solve All That...

Well, luckily for you, these problems become a blessing in disguise.

Because I have spent the last 25+ years putting together the world's most comprehensive collection of woodworking plans

These one-of-a-kind plans are drafted by hundreds of students and myself which you will NOT find anywhere else.

So what if I told you that you could get your hands on 16,000 woodworking projects...

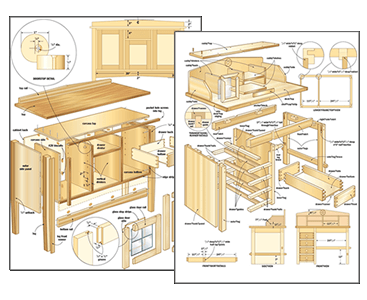

with already “done-for-you” plans that includes step-by-step instructions, drawings & blueprints...

So you can build stunning, professional woodworking projects -- easily, quickly & hassle free?

Introducing...

TedsWoodworking

"Earth's Largest Database of Woodworking Projects!"

Make 16,000 Projects With Step By Step Plans

...even if you don't have a large workshop or expensive tools!

So what makes a "perfect woodworking plan?"

Simply put, it must be detailed enough to leave nothing to guesswork yet simple enough for beginners. It must also contain complete instructions from start to finish.

Look at the features and see why our plans are 10x better than all "mass-market" plans:

As Featured On...

"Ted has an extensive selection of plans with amazing clarity...thumbs up!" - American Woodworker Magazine

Plus You Get FREE Monthly Plans For Life!

... and YOU GET TO CHOOSE your own custom plans too!

I draft plans every month for my students in my workshop classes.

I also take custom requests if you have a specific, unique project in mind.

Here is how it works:

- Project planning and design during one of our workshop classes

In addition to the 16,000 plans, we release new plans every month drafted from our workshop.

You will get lifetime access to a membership area where you can download these new plans monthly.

There are NO recurring fees, no expiry date.

We've been releasing new plans for several years now to thousands of woodworkers.

You can even request a plan to be drafted for you and I'll make sure it gets drafted in the next cycle.

Here are the types of plans we draft:

Types of Projects You Can Build Today

Just a small sample of over thousands of other projects

Plus Thousand More Projects!

List of Plans You Can Download:

Now you can build almost any kind of project with TedsWoodworking

Here is a partial list of all 16,000 plans included in TedsWoodworking.

There are many more categories that I can't fit on a single page. This is also an ever-growing list as we add new plans every single month.

- Arbor Projects

- Adirondack Chairs

- Artwork Display

- Bathroom Unit

- Box Designs

- Billiard/Pool Table

- Barn Plans

- Bed Plans

- Bedside Cabinets

- Bee Hive Plans

- Bench Projects

- Bird Feeders

- Birdhouse Plans

- Boat Plans

- Book Case Plans

- Changing Table

- Coat Rack

- Cabin Plans

- Cabinet Plans

- Carport Plans

- Cart Plans

- Cat House Plans

- CD/DVD Holder

- Cellar Projects

- Chair Plans

- Chest Designs

- Chicken Houses

- Children Rooms

- Clock Plans

- Coffee Tables

- Cold Frame Plans

- Compost Bin

- Computer Desk

- Containers

- Crafts and Gifts

- Cutting Boards

- Deck Plans

- Dollhouses

- Dog Houses

- Door Designs

- Dressers

- Drill Press

- Entertainment

- Furniture Plans

- Farmshop Plans

- Fences

- File Cabinet

- Fireplaces

- Frames

- Furnishings

- Kids Furniture

- Garage Plans

- Gazebos

- Greenhouses

- Guitars

- Gun Cabinets

- Gun Hidden Storage

- Hammocks

- Home Office

- Horse Barns

- Humidor Plans

- Hutch Plans

- Jig Plans

- Kitchen Projects

- Knife Block

- Lamps

- Landscaping

- Lathe Plans

- Mailbox

- Mantels

- Media Center

- Mirrors

- Music Boxes

- Ottoman Plans

- Outdoor Plans

- Pergolas

- Planters

- Playhouses

- Rabbit Houses

- Wooden Racks

- Router Plans

- Screens

- Scroll Saws

- Outdoor Sheds

- Shelves

- Signs & Displays

- Small Homes

- Squirrel Den Box

- Stools

- Storage Plans

- Swing Plans

- Table Plans

- Tool Boxes

- Trays

- Trellis Plans

- Utility Buildings

- Wooden Toys

- Wagon Designs

- Wind Generator

- Windmills

- Wishing Well

- & Many More!

Covers ALL Types of Projects From Large To Small

Small Crafts

Outdoor Projects

Furniture Designs

Workshop Benches & More!

16,000+

Total Number of Plans

24,000+

Satisfied Customers

173,226+

Total Projects Created

Plans So Detailed... It Practically Builds Itself!

All your plans comes with highly detailed schematics so there is no need for guesswork!

TedsWoodworking makes these 16,000 projects not only possible... but drop-dead simple...

I’ve seen plenty of plans and instructions out there…

and after reviewing them, I’m not surprised why many aspiring woodworkers – exceptionally talented people just like you – just give up after trying them!

Some of them are just a few simple images… and then you’re expected to figure out everything else on your own.

No diagrams, no 3D drawings, no lists.

Just a “good luck” and that’s about it.

TedsWoodworking gives you “total package” instruction and resources to empower you to get those projects done right the first time… and to avoid all the blunders and confusion!

It doesn’t matter what your current skill level is.

TedsWoodworking makes it easy to complete workshop, furniture, and LOTS of other projects… no matter whether you’re just starting out or you have years of experience!

With “hold-you-by-your-hand” detailed instructions, step by step plans and a wealth of other resources, you get everything you need to produce stunning results!

It doesn’t matter what your budget is.

Most of us don’t fully realize our woodworking talents because we think our projects are going to cost a bundle.

But in TedsWoodworking, you’ll get proven strategies for completing your costs for a fraction of what most retailers charge!

It doesn’t even matter if you’re not ready for a full-scale shop.

Maybe your “pro shop” is a few years off and you don’t need a full suite of tools and machines… but that’s perfectly OK.

You can take on these projects at your own pace… and develop solid skills and techniques that will help you tackle any kind of woodworking project!

Listen To What Our Satisfied Customers Are Saying:

I don't want you to take MY word for it.

Instead, I'd like you to see what a few of TedsWoodworking buyers have to say...

“The Best Collection of Project Plans I've Reviewed!”

“I’ve read numerous books and bought several online woodworking plans and this is clearly the best that is on the market in every aspect. It has got lots of different ideas and inspiration. Plans are detailed and the instructions are in-depth.

I’d rate this package as one of the best collection on woodworking plans I’ve reviewed. You simply must get this, especially if you are just getting started in woodworking. As far as I am concerned, this is a bargain. The level of detail will set a new standard in the field.”

Willie Stark - Chief Editor,

Woodworking, Valdosta

“Plans Are Super Easy To Read and Understand Unlike Others...”

“I just got this package a few days ago, and I’ve had a hard time putting it down. There are lots of full-color pictures, with thorough descriptions of every step in the project. These turned out to be even better than I’d hoped!

Plans are super easy to read and understand, unlike several others I looked online. I can’t wait to get started building some of the pieces and I have some projects picked out to start as soon as I can get the lumber! A valuable addition to my woodworking reference library. I would highly recommend it to anyone who’s interested in woodworking.”

Bradly Lerwill - Durham, UK

“An Excellent Investment For Anyone Starting Out”

“Of all the woodwork plans I have bought over the years, this is the best collection I have. Its an excellent resource for beginners as well as seasoned woodworkers. It includes tons of blueprints for different small crafts, furniture and outdoor projects and it’s simply outstanding…an excellent investment for anyone starting out.

I would loved to have had these when I was building my first outdoor deck. Considering the excellent content, and the quality of the plans itself, this package is quite a bargain.“

Melvin Jones- AWFS Association,

WLake Ariel PA

“I've Been Looking for Something Like This For the Longest Time...”

“I’ve been looking for something like this for the longest time. You get to learn how to design, detailed photographs of the projects, exploded blueprints, materials list and step by step instruction. It even shows you the different tools needed and how to use them and really explains the entire process to you.

If you want to get ideas on your project or build thousands of quality works in wood, you owe it to yourself to get this package.”

Kevin Roane - San Mateo, CA

Plus Many More Testimonials From Facebook Fans:

"I Can Build Things Now I Never Thought Possible!"

"The Amount of Content Simply Blew My Mind..."

See What Our Customers Have Built:

And Many More!

Here's Everything You Get In TedsWoodworking:

16,000 "Done For You" Plans

Download over 16,000 “done for you” plans with step-by-step blueprints and easy to follow instructions that makes the most challenging project a walk in the park!

From large outhouses to intricate crafts and furniture around the house, I’ve got EVERYTHING covered. You would be able to build any project you could ever imagine!

Lifetime Free Monthly Plans

Get monthly free plans for life. We draft new plans monthly and you'll get to download them for free.

You will get lifetime access to a membership area where you can download these new plans monthly.

There are NO recurring fees, no expiry date.

Custom Plans + Support

Request a custom plan drafted for you. If you have a specific project in mind, our team of craftsman will be able draft up a custom plan for you.

Plus, you get all the help you need to complete your project from our master woodworkers via email and forum support.

Access From Any Device

Access your plans from any device, anytime, anywhere - which makes it super convenient for you

View all your plans on any mobile / tablet device so you can view it while working at your shop

Online Access + DVDs & USB Thumbdrive

Get immediate lifetime access to all your plans in the members area.

You can also opt for the DVDs & USB thumbdrive of all current plans, training, bonuses and we’ll ship it to your mailbox.

Guides & Tutorial Videos

Download tons of included guides on techniques & invaluable resources to expand your skills.

Get access to an archive of tutorial videos covering fundamentals and advanced woodworking techniques.

Make Any Project Easy and Hassle-Free!

As you sit there reading this, I know you're thinking about all the different projects you're going to make...

and how woodworking is going to be a breeze when you buy TedsWoodworking Package.

Listen up closely... If you got plan to build any other woodwork project, TedsWoodworking will be invaluable to you.

- One-of-a-kind package that walks you step-by-step through the project

- Get "done-for-you" blueprints and plans for over 16,000 projects

- Get lifetime of monthly free plans with your purchase. You'll never run out of projects or ideas!

- Request custom woodworking plans from our workshop for that specific "hard to find" project

- Complete any project quickly, inexpensively and with professional results EVERY TIME.

Claim These 4 Exclusive Bonuses If You Order Today

If you get in today, I'll give you 4 special time-limited bonuses that will help you get going with your woodworking projects even faster...

Bonus #1

DWG/CAD Plan Viewer

The first bonus is the award winning "DWG/CAD Plan Viewer". Now you don't have to pay for overpriced CAD software.

A typical CAD software like AutoCAD will cost you a whooping $1985 on Amazon!

Dream it, Design it, Build it! This software allows you to edit, modify or even create your own woodworking plans. It will save you hundreds of dollars on "advice" that ends up not helping you at all.

Regular Price: $47 - Yours FREE!

Bonus #2

150 Premium Videos

You're also going to receive lifetime membership access to over 150 premium woodworking videos on a wide array of woodworking topics, hosted by veteran woodworkers.

It comes with easy-to-follow step by step video instructions and you can browse our huge selection of woodworking videos, including detailed instructional videos all designed to enhance your woodworking skills.

New videos are added constantly...

These hi quality premium videos are worth $77 if I sell this separately but you'll get free access if you order today.

Regular Price: $77 - Yours FREE!

Bonus #3

How To Start A Woodworking Business

Ever thought of making some money selling your woodwork? Now you can!

With the "How To Start A Woodworking Business" book, you'll learn how to turn your passion into profits.

This is a step-by-step detailed guide on how to make money selling your custom woodwork and it is a great addition to this package.

- Learn how to start quickly and operate successfully

- Marketing your services & what to sell to make money

- Locating suppliers and working with your competitor

- Licensing, accounting & tax matters you MUST know

- Getting help and contracting jobs to scale up your business

- And many many more...

Regular Price: $27 - Yours FREE!

And to top it all off, I'm going to do something I didn't originally plan on doing at all.

When I started planning TedsWoodworking, I knew this bonus would be invaluable for all woodworkers. I wanted to sell the next bonus individually for $39.00 but to sweeten this deal, I'm going to give it to you!

Bonus #4

Complete Woodworking Guides

As if that's not enough, you'll also be glad to know that I'm throwing the Complete Woodworking Guides.

It contains over 200 pages of woodworking tips and tricks with detailed drawings, diagrams and photos.

Think of this as the foundation for your woodworking plans. There's no fluff here.

It's 200 pages of solid, step-by-step and straightforward advice that sets you up for your woodworking projects. The guides covers all the bases, from working with hand tools to cutting dovetails and many more.

Regular Price: $39 - Yours FREE!

PLUS YOU GET FREE LIFETIME UPDATES:

Download Free Plans For Life

Here's how it works: Every month we release new plans drafted from our workshop.

You will get lifetime access to a membership area where you can download these new plans every month. There are NO recurring fees, no expiry date.

We've been releasing new plans monthly for several years now to thousands of woodworkers. Join our community and get free plans for life!

So Ted, How Much Does This Cost?

Now, you may believe a huge collection of plans such as this will be extremely expensive...

...and truth to be told it really should be considering the immense value that thousands of satisfied woodworkers are getting from our package.

Of course, when magazines and online sites sell EACH individual plan for $10-$20, it's only natural to think a package containing 16,000 plans and that I poured years of my life into creating might be unaffordable.

However, it's not!

I only felt right by making TedsWoodworking affordable for every woodworker, so I'm offering a limited-time, special launch discount...

So to celebrate this new launch... the price will be only $297 $197 $67

That's right. Your investment for the entire course is only $297 $197 $67.

That's a lifetime of woodworking projects on tap for the price of a fancy dinner.

But please let me warn you: this special launch offer will close soon and you won't be able to get in at this price after that even if you want to.

Once I start receiving more testimonials, I'm going to raise the price accordingly.

First I'll bump it up to $197.00...then to $297.00 and more...and it'll still be a bargain for what you're getting..

Click The 'Add To Cart' Button Below To Get Started:

TODAY'S PRICE: $67

Create The Projects You've Dreamed Of Today >>

This is a one-time purchase.

There are NO monthly fees

Here's Everything You'll Get:

- Instant Access To All 16,000 Projects with step-by-step details, drawings, plans, cutting & materials list and more... ($297 Value)

- Lifetime Membership Access - Get access to a ever-growing database of plans in our member's area

- Lifetime FREE Monthly Plans - Get free plans every month with no recurring fees or other charges ($39 Per Month Value)

- Free Custom Plan Request - Get a custom plan to your project, drafted by our team of craftsmen ($250 Value)

- Woodworking Guides & Videos - You'll get access to an archive of detailed guides & video tutorials covering all the fundamentals of woodworking techniques

- Option to have get everything on physical copies shipped to you

- 100% Risk-Free Money Back Guarantee

Plus These Amazing Bonuses:

- DWG & CAD Plan Viewer ($47 Value)

- 150 Premium Woodworking Videos ($77 Value)

- How To Start A Woodworking Business ($27 Value)

- Complete Woodworking Guides ($39 Value)

Get Started For A One Time Fee Of:

(This is a special launch offer only, I reserve the right to end this discount anytime after in 2 days)

Get Instant Access to 16,000 Projects Now

This is a one-time purchase. There are NO monthly fees.

Don't Say "Yes". Just Say "Maybe" & Give It A RISK-FREE Test-Drive For a Full 60 Days!

I hate seeing the word "guarantee" everywhere. What is it supposed to mean? Just words. Platitudes to get you to buy.

So, I'm making you more than just a guarantee. It's a personal promise to you.

I honestly believe this is the most complete woodworking package currently available ANYWHERE else... I would want the ground to open and swallow me whole if I thought you were disappointed. So here's the deal...

My 60 Day, "LOVE IT OR SHOVE IT" 100% Satisfaction Guarantee!

If this is not the most complete woodworking resource you've ever seen, simply email me and I will return 100% of your money back. No questions asked.

This my full 60 days IRON-CLAD money back guarantee to you.

Special Launch Offer Ending Soon:

Please let me warn you: this special launch offer will close soon and you won't be able to get in at this price after that even if you want to.

Because the TedsWoodworking Limitless Projects Club will soon be $39 per month.

But HERE… on THIS page… the price is a one-time fee of just $67. And this page is going away very soon. I reserve the right to end this discount at anytime without warning after in 2 days

So you have a choice to make.

And I think the choice is an easy one!

For the price of a night out, you can take any and all headaches out of building quality woodwork projects - FOREVER.

Think about all the time, energy and cost you'll save with a collection of 16,000 plans at your fingertips.

Even better, after you order you will get INSTANT ACCESS to all the plans. There is no need to wait for shipping and you can get the information you want in seconds from now!

With thousands of happy users it's time for you to get in on the action. So don't waste any time.

Take action right now:

This is a one-time purchase. I reserve the right to end this discount at anytime without warning after in 2 days

As soon as you hit "Add To Cart", you'll be able to get an email that gives you the download access

You can download the entire "TedsWoodworking" 16,000 plansand all the bonuses right now. Plus you'll get the option of getting everything on a snazzy USB or DVDs.

You can be going through all my plans in just a few minutes from now and get started on your project immediately.

Experience the joy... the satisfaction, to know with 100% certainty that your project will turn out EXACTLY the way you want it to look.

All you have to do to get started is click the ‘Add to Cart’ button today:

TODAY'S PRICE: $67

Start Your Next Project Today >>

This is a one-time purchase.

There are NO monthly fees

P.S: Remember...you have my 100% Risk Free Unconditional Money-Back Guarantee. I am 110% sure you will be happier than a 5 year old on Christmas morning with your plans. But if for any reason you are not, no worries. Your investment is guaranteed for a full 60 days.

P.P.S: This is a TIME-SENSITIVE OFFER! You will never have the opportunity to invest in this package again at this price once the introductory offer ends.

Got Questions?

How do i get access to the plans? Is it something sent to my house?

We’re in the digital age and one of the things I’m really excited about is how we deliver this program.

So the way it works is you’re going to enter your credit card information on the next page. After that, you’ll get instant access to the package. It’s kind of a membership site, but don’t worry about a monthly membership fee or anything like that.

You will pay only once and that’s all you pay. There’s no additional charges, no hidden charges, no nothing like that.

For a small fee I will also ship worldwide, the DVDs of all the plans and bonuses.

I don't have any space for a workshop. Will this still work for me?

Fact is, you don't need a large space or expensive tools to build many of the projects. I started off with a 7x8 size workshop and many of my best pieces came from that shop.

I've included many small mobile workbenches you can build right away as well. Many of my plans do not require professional machinery or even a router.

Is there a monthly fee of any kind?

NO. Not if you accept this deal right now. This is a one-time fee of $67 for a lifetime of plans

Why a one-time fee? Won’t you lose money long term?

Not really. It is a digital product after all. I suppose if everyone were to get this deal then yeah, eventually the time I spend every month creating the 5 new plans wouldn’t earn me an income. Which is why I am taking this page down soon!

Can I sell the projects I make with your plans?

Absolutely. You can sell the projects you build with our plans. Many of my customers went on to make a sizable side income by selling projects they make.

What if I'm new to this and I'm just bad?

I believe anyone can start woodworking.

I've got a whole bunch of easy starter plans you can try. It doesn't take a lot of tools or materials to build a lot of the starter projects.

If you can do small steps - cut a board in half, glue pieces.... then it is not that much of a leap to join the boards. Before you know it, you have a completed project. In the end, it is a simple process. It just a series of multiple steps.

My plans will guide you through everything. One step at a time.

Can I buy plans separately? I only need a few specific plans.

Look. It doesn’t make sense to purchase one plan when I’m offering this deal for my entire package at only $67. I’ve sold my plans separately for a lot more but I’ve bundled everything together due to repeated requests.

Think about it this way: Even if you don’t intend to use most of the plans, this is a great deal any way you look at it.

For just one low price of $67, you can keep the rest of my plans forever. It will be handy in the future to have access to this huge collection of woodworking plans.

I can't afford tools or materials to build my project

If that’s the case… this is perfect for you… because you will learn exactly what you need to build a project you’re interested in. So there’s no wasting your money on tools you won’t use. Just buy exactly what I tell you and follow my instructions. Then move onto the next and buy the new tools you need (if any)… Simple and cost effective!

Simply get what you need for the projects you want to build at anytime. I'll also show you ways to get lumber and materials for far less than what you pay retail.

Are there a lot of beginner plans in this?

YES. Most of these plans are beginner plans. With the rest being intermediate and some being expert plans.

But keep in mind, given the quality of these plans, you might surprise yourself with your ability to quickly expand the projects you can do.

I really want this, but I want to make sure it's safe. How does your guarantee work?

Obviously, you should only give your credit card to companies that you can trust 100%. That’s why we use ClickBank. ClickBank is an established credit card processing company that has been in business since 1997.

They provide credit card clearing and payment services for tens of thousands of merchants all over the internet.

When you place your order with us, you will connect to ClickBank through a secure server, which makes it virtually impossible for a hacker to intercept your information.

And the 60 day money back guarantee is my personal promise to you. If you don’t like it for any reason, just drop me an email and I will refund you the full amount within 48 hours or less.

There will be no questions, no fineprint, no B.S

Why are you discounting this so much? What's the catch?

There is no catch. I'm running a limited launch offer so I want to reward visitors who take fast action. When this goes live I will charge $39 per month and it WILL be worth it. But for some folks lucky enough to be here, the price is a ONE-TIME fee of $67.

How long do I have access to the plans?

You have LIFETIME access to all the plans in the members area. Your membership never expires and you can login anytime to download more plans. Whats more, I draft new plans every month so you'll always have new ideas, new projects to make

Once Again, Here's Everything You'll Get:

- Instant Access To All 16,000 Projects with step-by-step details, drawings, plans, cutting & materials list and more... ($297 Value)

- Lifetime Membership Access - Get access to a ever-growing database of plans in our member's area

- Lifetime FREE Monthly Plans - Get free plans every month with no recurring fees or other charges ($39 Per Month Value)

- Free Custom Plan Request - Get a custom plan to your project, drafted by our team of craftsmen ($250 Value)

- Woodworking Guides & Videos - You'll get access to an archive of detailed guides & video tutorials covering all the fundamentals of woodworking techniques

- Option to have get everything on physical copies shipped to you

- 100% Risk-Free Money Back Guarantee

Plus These Amazing Bonuses:

- DWG & CAD Plan Viewer ($47 Value)

- 150 Premium Woodworking Videos ($77 Value)

- How To Start A Woodworking Business ($27 Value)

- Complete Woodworking Guides ($39 Value)

Get Started For A One Time Fee Of:

Get Instant Access to 16,000 Projects Now

This is a one-time purchase. There are no monthly fees or hidden costs. I reserve the right to end this discount at anytime without warning after in 2 days

WAIT! GET YOUR FREE PLANS

I totally understand

you are not ready to commit to trying out TedsWoodworking right now and I respect that...

I totally understand

you are not ready to commit to trying out TedsWoodworking right now and I respect that...

So

what I want to do is to give you 50 FREE "done-for-you" plans plus "The Art of Woodworking" book

valued at $39.95. ABSOLUTELY FREE!